When it comes to choosing the right material for your countertops or other surface applications, it's important to consider factors like durability, aesthetics, and maintenance requirements. High pressure laminate (HPL) and solid surface are two popular options that offer unique features and benefits. In this article, we will delve into the characteristics of both HPL and solid surface materials, highlighting their pros and cons, to help you make an informed decision. So, let's explore the differences between high pressure laminate and solid surface and determine which one is better suited for your needs.

Understanding High Pressure Laminate:

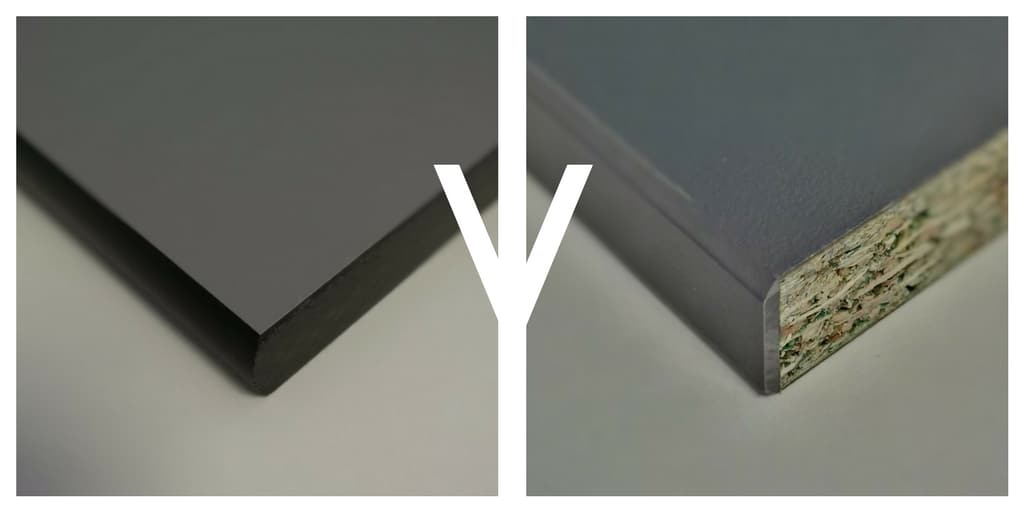

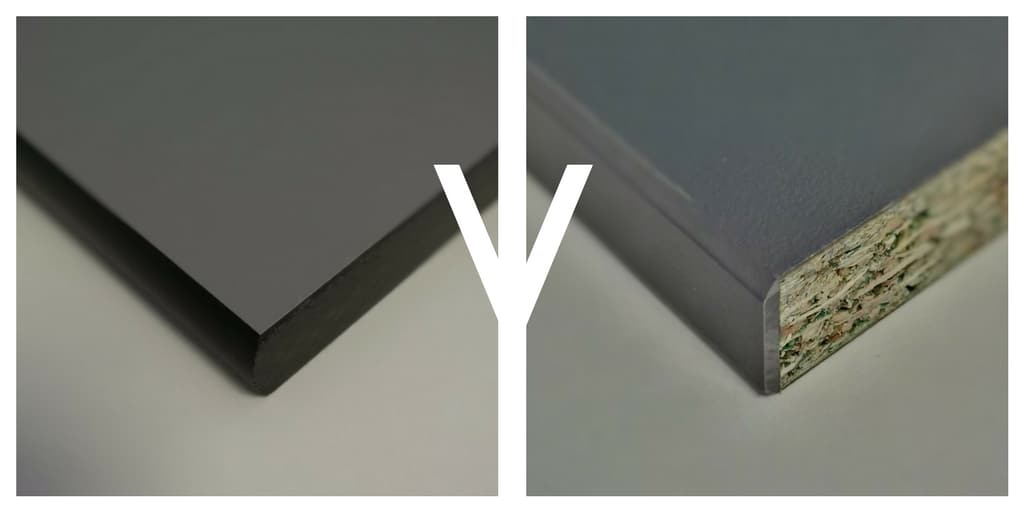

High pressure laminate, commonly known as HPL, is a versatile and cost-effective surfacing material. It is made by layering multiple sheets of resin-impregnated kraft paper under high heat and pressure. The top layer features a decorative design or pattern, which is protected by a clear melamine overlay. HPL is available in a wide range of colors, patterns, and textures, allowing for endless design possibilities.

Advantages of High Pressure Laminate:

Durability: HPL is highly resistant to scratches, stains, and impact, making it suitable for high-traffic areas.

Cost-effective: Compared to solid surface, HPL is generally more affordable, making it a budget-friendly option for homeowners and businesses.

Easy maintenance: HPL surfaces are easy to clean and require minimal maintenance. Regular wiping with a mild detergent is usually sufficient to keep them looking pristine.

Limitations of High Pressure Laminate:

Heat sensitivity:

HPL is sensitive to heat and can be damaged by hot pans or pots. Using trivets or hot pads is recommended to protect the surface.

Visible seams:

Due to the way HPL is manufactured, visible seams may be present in larger installations, which can affect the overall aesthetic appeal.

Understanding Solid Surface:

Solid surface is a synthetic material composed primarily of acrylic or polyester resins mixed with minerals and pigments. It offers a seamless and non-porous surface that can be fabricated into various shapes and designs. Solid surface countertops have gained popularity for their versatility and modern appeal.

Advantages of Solid Surface:

Seamless installation:

Solid surface allows for seamless joints, creating a sleek and uninterrupted surface. This makes it an excellent choice for large countertops or curved installations.

Stain resistance:

Solid surface is non-porous, making it resistant to stains and bacterial growth. It is easy to clean and maintain.

Repairable: In the event of scratches or minor damages, solid surface can be repaired and restored to its original condition by sanding or buffing.

Limitations of Solid Surface:

Susceptible to heat damage:

Similar to HPL, solid surface is prone to heat damage. Direct contact with hot objects can cause discoloration or deformation.

Higher cost:

Compared to HPL, solid surface tends to be more expensive, which can impact budget considerations.

Making the Decision: Choosing between high pressure laminate and solid surface depends on your specific needs and preferences. If budget is a major concern and you require a durable and versatile material, HPL can be a suitable choice. On the other hand, if you prioritize a seamless and customizable surface with higher resistance to stains, solid surface might be the better option.

Conclusion:

In the comparison between high pressure laminate and solid surface, both materials offer unique advantages and limitations. High pressure laminate is a cost-effective option with a wide range of design possibilities, while solid surface provides seamless aesthetics and better stain resistance. Consider your budget, desired aesthetics, and maintenance requirements when making the decision. Ultimately, both materials have their merits, and choosing the right one will depend on your specific needs and priorities

When comparing High Pressure Laminate (HPL) and Solid Surface materials, it's important to consider their characteristics and intended uses to determine which one is better suited for your specific needs. Here are some key factors to consider:

Appearance and Design:

Both HPL and Solid Surface offer a wide range of colors, patterns, and finishes. HPL is typically made of multiple layers of paper and resin, while Solid Surface is composed of a homogeneous mixture of mineral dust and acrylic resin. Solid Surface can provide a seamless and smooth appearance since it can be seamlessly joined together, while HPL may have visible seams.

Durability:

Solid Surface is known for its durability and resistance to scratches, stains, and heat. It is non-porous, which makes it more resistant to moisture and bacterial growth. HPL is also durable, but it can be more susceptible to scratches and heat damage. It is more resistant to moisture compared to wood-based laminates, but not as much as Solid Surface.

Maintenance:

Both HPL and Solid Surface are relatively easy to maintain. HPL can be cleaned with mild soap and water, while Solid Surface can be cleaned with non-abrasive household cleaners. Solid Surface can be repaired if it gets scratched or damaged, whereas HPL may require replacing the entire sheet if damaged.

Applications:

HPL is commonly used for countertops, cabinets, and furniture surfaces. It is a cost-effective option that offers a wide variety of designs. Solid Surface, on the other hand, is often used for countertops, sinks, and vanities, as it can be formed into various shapes and has a seamless appearance.

Cost:

HPL is generally more affordable than Solid Surface. The cost of Solid Surface can vary depending on the brand and design, but it tends to be higher than HPL.

In summary

both High Pressure Laminate and Solid Surface have their advantages and considerations. HPL is a cost-effective option with a wide range of designs, while Solid Surface offers durability, seamless appearance, and resistance to scratches and stains. Ultimately, the choice between the two materials depends on your specific requirements, budget, and aesthetic preferences.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti

Runasimi