As an essential material in modern construction and furniture manufacturing, fireproof boards have become highly popular due to their fire resistance, moisture protection, and durability. These properties make them ideal for creating safer living and working environments. However, like any building material, fireproof boards, especially their veneers, can face quality challenges during installation and usage. These issues can impact their appearance, functionality, and longevity.

In this article, we will delve into the common quality problems of fireproof board veneers and provide practical solutions to help maintain their performance and appearance over time.

1. The Role of Fireproof Board Veneers in Construction and Furniture

Fireproof boards have a wide range of applications in the construction and furniture sectors, where fire safety and long-term durability are critical. They are widely used for:

Wall cladding in buildings and homes.

Cabinetry and furniture in residential and commercial spaces.

Interior partitions where additional fire resistance is required.

While the core material of fireproof boards is built to withstand high temperatures, veneer issues can compromise their performance and visual appeal. Addressing these issues promptly is essential for maintaining the board’s intended benefits.

2. Common Quality Problems in Fireproof Board Veneers

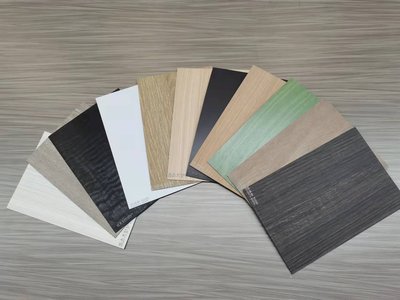

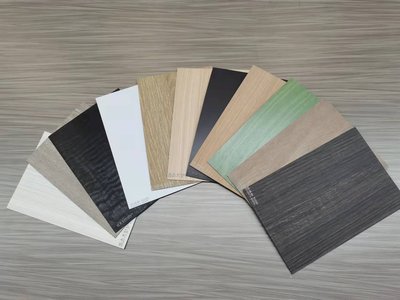

Fireproof board veneers are thin layers applied to the board’s surface to enhance both aesthetics and durability. However, the following common issues often arise:

Warping and Deformation

Warping or bending of fireproof board veneers occurs due to improper construction techniques or incorrect glue application. This deformation affects the appearance and usability of the finished product and may lead to uneven surfaces.

Glue Peeling

If glue is applied unevenly or if poor-quality glue is used, the bond between the fireproof board and veneer weakens. Glue peeling can result in detachment, causing the veneer to fall off over time.

Visible Color Difference

Color inconsistencies within the same batch of fireproof boards can negatively impact the overall visual appeal, especially if the boards are used in highly visible areas. Such color differences are often due to variations in raw materials or production methods.

Surface Scratches and Damage

During transportation and installation, fireproof board surfaces are prone to scratches, which can ruin the appearance. These scratches may also expose the material underneath, making it more susceptible to wear and tear.

3. Effective Solutions for Preventing and Resolving Veneer Issues

Preventing quality issues in fireproof board veneers requires a combination of rigorous inspection, quality materials, and proper handling throughout the construction process. Here are some actionable steps to address these common issues.

A. Strict Control Over Construction Quality

i. Surface Preparation

Before applying veneers, inspect and prepare the substrate. Ensure it is flat, dry, and free of contaminants such as dust, oil, or debris. This step helps improve the adhesion of the veneer.

ii. Proper Glue Selection and Application

Choose high-quality glue specifically designed for fireproof boards and follow the manufacturer’s guidelines for application. Proper glue application ensures even bonding and prevents warping or peeling.

iii. Maintain Optimal Humidity Levels

Environmental conditions like humidity can impact veneer quality. During installation, aim to keep the surrounding humidity at a balanced level to avoid issues caused by excess moisture or dryness.

B. Strengthen Material Inspection and Procurement

i. Select Quality Materials from Reputable Suppliers

Purchase fireproof boards from certified manufacturers and check for product certificates and quality inspection reports. These documents ensure the material complies with fire safety and quality standards.

ii. Conduct Batch Sampling for Consistency

Perform sampling inspections for each batch to check for color and texture consistency. By addressing inconsistencies early, you can prevent noticeable color differences in finished products.

C. Protect Finished Products from External Damage

i. Take Precautions During Transportation and Storage

Handle fireproof boards with care during transportation and storage. Use protective materials and avoid placing heavy objects on the boards to prevent scratches, dents, and impacts.

ii. Conduct Regular Maintenance and Inspection

For fireproof boards in high-use areas, regular maintenance is key. Check for any signs of glue peeling, warping, or other wear and promptly address these issues.

4. Preventive Measures and Best Practices for Long-Term Quality

Long-term prevention of veneer issues relies on thorough quality control at every stage, from material selection to post-installation maintenance. The following measures can help ensure a lasting, quality finish:

Enhance Training and Supervision for Construction Personnel

Investing in the training and supervision of personnel who handle and install fireproof boards is essential. Proper training ensures correct construction techniques and minimizes the risk of errors.

Enforce Rigorous Material Inspection Standards

Enforcing strict inspection standards helps maintain quality control. This approach involves monitoring raw materials and ensuring they meet fire safety and quality standards.

Encourage a Strong Culture of Finished Product Protection

From design to production and throughout the construction process, emphasize finished product protection. This focus reduces the likelihood of external factors impacting the final quality.

Establish a Reliable After-Sales Service System

Implementing a responsive after-sales service system can make a significant difference. Quick responses to customer concerns about product quality help build trust and ensure user satisfaction.

Conclusion: Ensuring Quality and Longevity in Fireproof Board Veneers

Quality problems in fireproof board veneers, such as warping, glue peeling, color inconsistency, and surface damage, are common but manageable. By adopting a proactive approach that includes rigorous material inspection, proper construction practices, and consistent maintenance, builders and manufacturers can enhance the lifespan and performance of fireproof boards. With these strategies, fireproof board veneers will continue to be a reliable, high-quality choice for construction and furniture applications.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti

Runasimi