As major holidays like the Spring Festival approach, fire incidents caused by improper decoration materials and electrical overload become more frequent. Many of these accidents could be prevented with the correct selection of fire-resistant building materials. However, most people are unclear about what fire ratings actually mean and how to choose the safest option for their homes, offices, or commercial spaces.

This guide explains the different grades of fire-resistant materials, how to interpret fire safety standards, and how to choose the right materials for various environments — helping you protect lives, property, and long-term investments.

What Are Fire-Resistant Material Grades?

Fire-resistant materials are classified based on their combustion performance, including how easily they ignite, how fast flames spread, how much heat they release, and how toxic the smoke is.

According to GB 8624-2012, the national fire safety classification standard, building materials are divided into four major fire-resistance grades:

Grade A – Non-combustible materials

Grade B1 – Flame-retardant materials

Grade B2 – Combustible materials

Grade B3 – Flammable materials

A widely accepted safety principle is:

Grade A or B1 materials must be used in public spaces, and Grade A materials must be used in high-risk areas.

Let’s explore each grade in detail.

Grade A Fire-Resistant Materials (Non-Combustible)

Key Characteristics

Do not ignite when exposed to fire

Do not release flammable gases

Produce extremely low smoke and toxicity

Maintain structural integrity under high temperatures

Common Grade A Materials

Cement board

Concrete

Gypsum board

Mineral wool panels

Glass, ceramics, and metal

Mortar and inorganic insulation materials

Typical Applications

Grade A materials are mandatory in high-risk and critical safety zones, including:

Stairwells and emergency exits

Electrical rooms and machine rooms

Underground basements and parking garages

Fire partitions and evacuation corridors

Best Use Case

Choose Grade A fireproof materials when human evacuation safety and fire containment are top priorities. These materials offer the highest level of fire protection and regulatory compliance.

Grade B1 Fire-Resistant Materials (Flame-Retardant)

Key Characteristics

Common Grade B1 Materials

Typical Applications

Grade B1 materials are widely used in:

Office buildings and shopping malls

Hotels, hospitals, and schools

Residential corridors and ceilings

Commercial wall cladding and partitions

Best Use Case

If you need a balance between aesthetics, performance, and safety, Grade B1 flame-retardant materials are the most practical and cost-effective solution for most interior spaces.

Grade B2 Fire-Resistant Materials (Combustible)

Key Characteristics

Common Grade B2 Materials

Natural solid wood

Paper-based decorative boards

Certain composite flooring materials

Non-treated wood veneers and panels

Typical Applications

Private residential interiors

Low-risk rooms such as bedrooms and living spaces

Decorative elements in controlled environments

Important Note

In public buildings, Grade B2 materials are generally restricted to limited decorative areas and must often be used together with fire-retardant coatings or protective systems.

Grade B3 Fire-Resistant Materials (Highly Flammable)

Key Characteristics

Applications

Grade B3 materials are no longer recommended for use in modern construction and are often prohibited in regulated building projects.

Safety Verdict

Avoid Grade B3 materials entirely — especially in enclosed spaces, commercial buildings, or areas with high occupancy.

How to Choose the Right Fire-Resistant Materials

Selecting fire-resistant materials is not just about price or appearance. It requires a risk-based approach that considers space usage, building type, and fire safety regulations.

1. Choose Based on Application Scenario

| Area Type | Recommended Fire Rating |

| Kitchens, machine rooms, power rooms | Grade A |

| Stairwells, evacuation routes, basements | Grade A |

| Offices, malls, hotels, corridors | Grade B1 or higher |

| Residential living rooms, bedrooms | Grade B1 preferred; B2 acceptable in limited areas |

2. Verify Fire Test Reports

Always require:

Official fire safety test reports issued by nationally recognized testing institutions

Documents with a CMA (China Metrology Accreditation) mark

Confirmation that the product model matches the test report

Never rely solely on sales claims or packaging labels.

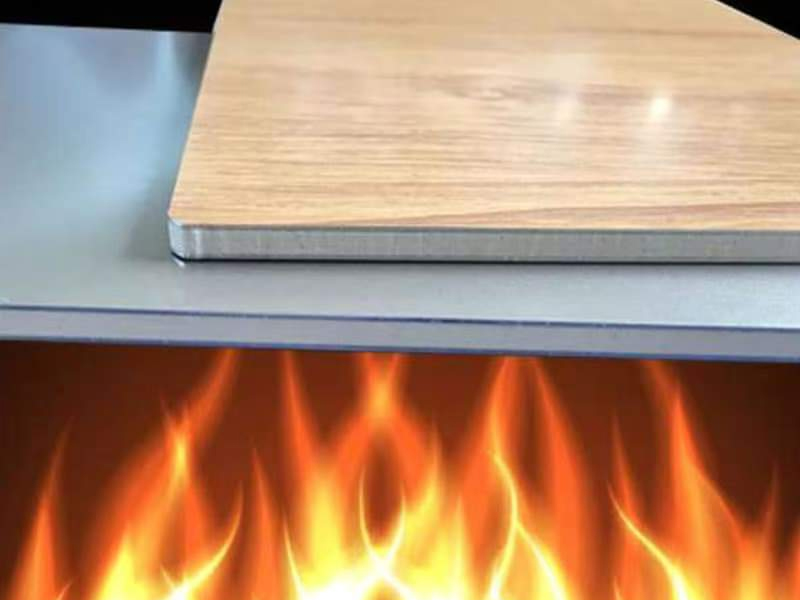

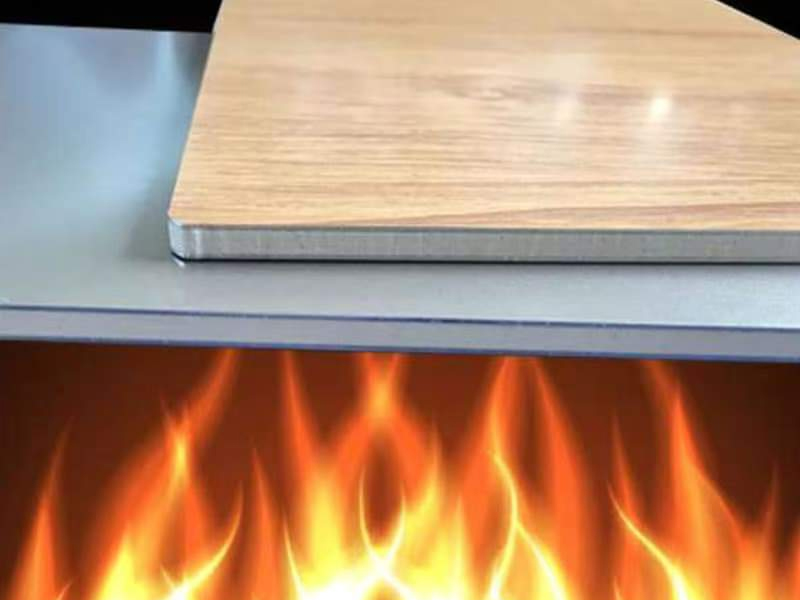

3. Pay Attention to Composite Materials

Many decorative products — such as aluminum composite panels, fireproof boards, wall cladding panels, and laminate sheets — are multi-layered.

⚠️ The fire rating depends primarily on the core material, not just the surface finish.

Always confirm:

Core material combustion grade

Smoke density and toxicity performance

Heat release rate classification

4. Consider Installation and System Design

Even the best fire-resistant materials can fail if installed incorrectly.

Best practices include:

Using fire-resistant sealants and adhesives

Installing metal fire-rated supports instead of plastic frames

Ensuring proper sealing around joints, penetrations, and transitions

Fire safety is a system-level design, not just a product choice.

Common Misconceptions About Fireproof Materials

❌ Myth 1: Fire-resistant boards are completely non-combustible

Not true. Most so-called “fireproof boards” fall under Grade B1, meaning they are flame-retardant but not fully non-combustible. Only Grade A materials are truly non-combustible.

❌ Myth 2: Solid wood (Grade B2) can be used freely

In private residences, limited use is acceptable. However, in public buildings, B2 materials often require fire-retardant coatings and strict quantity controls.

❌ Myth 3: Thicker materials mean better fire resistance

Thickness alone does not determine fire performance. What matters more is:

Core material composition

Flame spread rating

Smoke toxicity classification

Heat release characteristics

Why Fire-Resistant Material Selection Matters More Than Ever

Modern buildings emphasize:

This increases fire load and evacuation complexity. Choosing proper fire-resistant materials directly impacts:

In many jurisdictions, improper material use can lead to failed fire inspections, fines, mandatory renovation, or business shutdowns.

Quick Buyer Checklist for Fireproof Materials

Before purchasing, confirm:

✔ Fire rating certificate (Grade A / B1 / B2)

✔ Official test report from accredited lab

✔ Core material fire performance

✔ Smoke density and toxicity level

✔ Product model matches documentation

✔ Compatibility with fire-rated adhesives and systems

✔ Compliance with local building codes

Final Thoughts: How to Make the Right Fire Safety Choice

Understanding fire-resistant material grades is essential for building safer homes and commercial environments.

Grade A materials offer the highest protection and should be used in all high-risk and evacuation areas.

Grade B1 materials provide excellent flame-retardant performance and are ideal for most interior decorative applications.

Grade B2 materials should be used cautiously and primarily in private, low-risk spaces.

Grade B3 materials should be avoided altogether.

By verifying certifications, understanding core materials, and selecting products based on real application risks — not just price or appearance — you ensure both regulatory compliance and long-term fire safety.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti

Runasimi