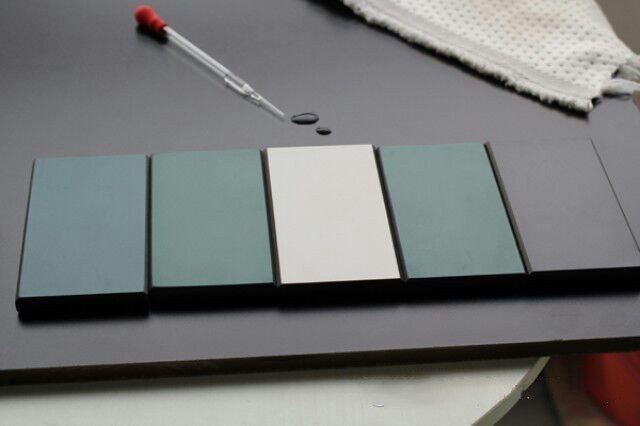

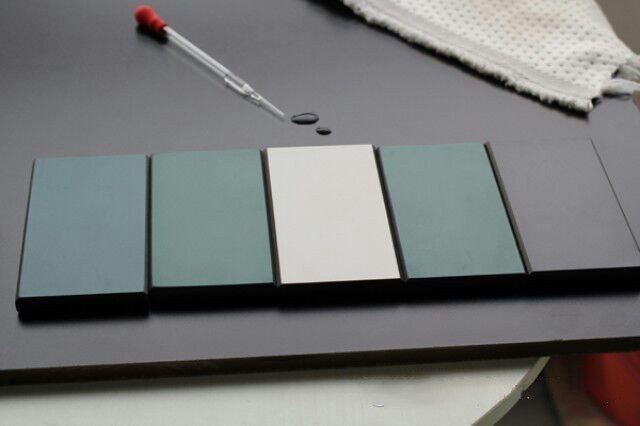

Choosing the right surface material is one of the most critical decisions in architectural design, interior decoration, and commercial construction. Among today’s most widely used materials, resin panels and compact laminate panels stand out for their durability, aesthetics, and performance versatility. However, while these materials may appear similar at first glance, they differ significantly in composition, structural strength, fire resistance, environmental performance, cost, and application suitability.

In this comprehensive guide, we present a detailed, professional comparison of resin panels vs. compact laminate panels, helping designers, contractors, and property owners select the best solution for residential, commercial, and industrial environments.

What Are Resin Panels?

Resin panels, often referred to as artificial stone panels or solid surface resin boards, are composite materials made primarily from synthetic resins such as epoxy resin, unsaturated polyester resin, or acrylic resin. These resins are blended with mineral fillers like calcium carbonate or aluminum hydroxide, then cast, cured, and polished into rigid decorative boards.

Key Characteristics of Resin Panels

Smooth, seamless appearance

Can be translucent or semi-transparent

Easily molded into complex shapes

Warm tactile feel

Suitable for custom fabrication

Resin panels are prized for their high aesthetic value, allowing designers to create surfaces that mimic marble, onyx, terrazzo, or artistic stone effects while maintaining consistent color and texture throughout the slab.

What Are Compact Laminate Panels?

Compact laminate panels, also known as HPL compact boards or solid phenolic panels, are manufactured by pressing multiple layers of kraft paper impregnated with phenolic resin, topped with a decorative layer impregnated with melamine resin. These layers are bonded under extreme heat (approximately 150°C) and high pressure (around 1430 psi) to create an ultra-dense, non-porous structural panel.

Key Characteristics of Compact Laminate Panels

Extremely high density and rigidity

Excellent fire resistance

Outstanding water and moisture resistance

Exceptional impact and abrasion resistance

Long service life even in harsh environments

Compact laminate panels are widely recognized as one of the strongest architectural surface materials, suitable for both interior and exterior use.

Resin Panels vs. Compact Laminate Panels: Core Differences

Let’s examine how these two materials compare across the most important performance and design factors.

1. Material Composition

Resin Panels

Resin panels consist of:

Synthetic resin base (epoxy, acrylic, polyester)

Mineral fillers (calcium powder, aluminum hydroxide)

Pigments and decorative inclusions

This structure creates a homogeneous, stone-like surface that can be cut, thermoformed, and seamlessly jointed.

Compact Laminate Panels

Compact laminate panels consist of:

Multiple layers of kraft paper

Phenolic resin impregnation

Decorative melamine surface layer

High-pressure compression

This layered structure results in a solid, load-bearing panel with exceptional mechanical strength.

Bottom line: Resin panels are cast composites, while compact laminates are high-pressure laminated structural boards.

2. Physical Properties and Structural Performance

Resin Panels

Moderate to high hardness

Smooth and non-porous surface

Good sound insulation

Flexible design shaping capabilities

Slightly lower impact resistance compared to compact laminate

Compact Laminate Panels

Extremely high density

Outstanding impact resistance

High bending strength and rigidity

Suitable for self-supporting structures

Resistant to warping, cracking, and deformation

Conclusion: For environments requiring maximum load-bearing strength, compact laminate panels significantly outperform resin panels.

3. Fire Resistance Performance

Resin Panels

Generally combustible

May soften, melt, or emit harmful gases under high temperatures

Not suitable for high fire-risk environments without fire-retardant additives

Compact Laminate Panels

Naturally flame-retardant

Self-extinguishing when exposed to fire

Do not drip molten material

Emit very low smoke and toxic gases

Result: Compact laminate panels offer superior fire safety performance, making them ideal for public buildings, laboratories, hospitals, and high-occupancy environments.

4. Moisture and Water Resistance

Resin Panels

Excellent water resistance

Non-porous surface prevents moisture penetration

Suitable for wet areas such as bathrooms and kitchens

Compact Laminate Panels

100% waterproof through the entire thickness

Do not swell, delaminate, or deform in humid environments

Suitable for direct water exposure and outdoor use

Verdict: Both perform well in moisture-rich spaces, but compact laminate provides superior long-term dimensional stability in extreme humidity.

5. Chemical and Corrosion Resistance

Resin Panels

Good resistance to mild acids and cleaning agents

Vulnerable to strong alkaline substances and solvents

Prolonged chemical exposure may cause surface dulling

Compact Laminate Panels

Outstanding resistance to acids, alkalis, solvents, and disinfectants

Available in chemical-resistant grades for laboratories

Maintains structural integrity in harsh industrial conditions

Conclusion: For chemically aggressive environments, compact laminate panels dominate.

6. Durability and Lifespan

Resin Panels

Compact Laminate Panels

Extremely scratch-resistant

Superior abrasion and impact resistance

Typical lifespan: 15–30 years or more, even in demanding applications

Result: Compact laminate panels deliver longer service life and lower replacement costs over time.

7. Aesthetic Performance and Design Flexibility

Resin Panels

Can be translucent or backlit

Seamless joints

Easily thermoformed into curved or sculptural designs

Ideal for artistic and luxury interiors

Compact Laminate Panels

Available in thousands of colors, wood grains, stone patterns, and textures

Matte, gloss, anti-fingerprint, and textured finishes

More rigid, less suitable for complex shaping

Summary: Resin panels excel in high-end decorative aesthetics, while compact laminate excels in functional architectural uniformity.

8. Weight and Installation

Resin Panels

Compact Laminate Panels

Conclusion: Resin panels offer greater installation flexibility, while compact laminate panels require more robust handling but provide higher structural reliability.

Applications: Where Each Material Performs Best

Best Applications for Resin Panels

Resin panels excel where visual impact, seamless aesthetics, and custom shaping are priorities.

Best Applications for Compact Laminate Panels

Compact laminate panels are ideal for high-traffic, high-humidity, fire-sensitive, and structurally demanding environments.

Resin Panels vs. Compact Laminate Panels: Summary Comparison Table

| Feature | Resin Panels | Compact Laminate Panels |

| Main Materials | Resin + mineral fillers | Kraft paper + phenolic/melamine resin |

| Manufacturing | Casting and curing | High-temperature, high-pressure lamination |

| Fire Resistance | Moderate | Excellent (self-extinguishing) |

| Water Resistance | High | Extremely high (100% waterproof) |

| Impact Resistance | Good | Excellent |

| Chemical Resistance | Moderate | Superior |

| Design Flexibility | Excellent (curved, translucent) | Moderate |

| Structural Strength | Medium | Very high |

| Typical Lifespan | 10–15 years | 15–30+ years |

| Best Use | Decorative interiors | High-performance environments |

Price Comparison in the 2026 Market

Material pricing fluctuates based on raw material costs, thickness, brand positioning, and functional customization. Below are typical pricing ranges:

Compact Laminate Panels

Standard grades: RMB 150–500/m²

Premium/imported brands: RMB 600–1200+/m²

Thicker panels (8mm–12mm) significantly increase cost

Resin Panels

Price Influencing Factors Comparison

| Factor | Compact Laminate | Resin Panels |

| Thickness | Strong price increase per mm | Moderate increase |

| Brand | High premium | Lower brand gap |

| Functional Upgrades | Chemical resistance, UV resistance increase cost | Translucency, 3D textures increase cost |

| Installation Complexity | Higher labor cost | Lower labor cost |

Purchasing Recommendations

Choose Compact Laminate Panels If You Need:

Maximum durability

Fire-retardant performance

Chemical resistance

Outdoor or wet-area applications

Long-term lifecycle cost efficiency

Choose Resin Panels If You Need:

Luxury aesthetics

Seamless joints

Translucent or artistic effects

Curved or sculptural surfaces

Lower initial project cost

Frequently Asked Questions

1. Which is better: resin panels or compact laminate panels?

Neither is universally better. Compact laminate panels excel in performance and durability, while resin panels dominate in aesthetics and design flexibility. The best choice depends on your application requirements.

2. Are compact laminate panels fireproof?

Compact laminate panels are flame-retardant and self-extinguishing, making them suitable for fire-sensitive environments such as hospitals, schools, and commercial buildings.

3. Can resin panels be used in bathrooms?

Yes. Resin panels have excellent moisture resistance and are commonly used in bathrooms, vanity tops, and wet-zone wall cladding.

4. Which material lasts longer?

Compact laminate panels generally have a longer service life, often exceeding 20 years in demanding environments, while resin panels typically last 10–15 years under heavy use.

Conclusion

Both resin panels and compact laminate panels offer outstanding performance, but they are designed for different functional priorities. Resin panels excel in visual impact, seamless design, and creative freedom, making them ideal for decorative interiors and luxury architectural features. Compact laminate panels, on the other hand, dominate in structural strength, fire resistance, moisture durability, and chemical stability, making them indispensable in high-traffic commercial, industrial, and public-sector environments.

By carefully evaluating design goals, environmental exposure, safety standards, maintenance expectations, and lifecycle costs, you can confidently select the material that delivers the best performance and return on investment for your project.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti

Runasimi