Compact laminate boards, also known as compact boards, have become one of the most sought-after composite panels in modern construction and interior design. Their popularity stems from their durability, resistance to fire, water, and impact, as well as their excellent sound and thermal insulation capabilities. These qualities make them a preferred choice for architects, designers, and builders worldwide. However, with the growing demand comes the risk of counterfeit or substandard products in the market. This article explores the main types of compact laminate boards and provides a detailed guide on how to identify authentic ones.

What Are Compact Laminate Boards?

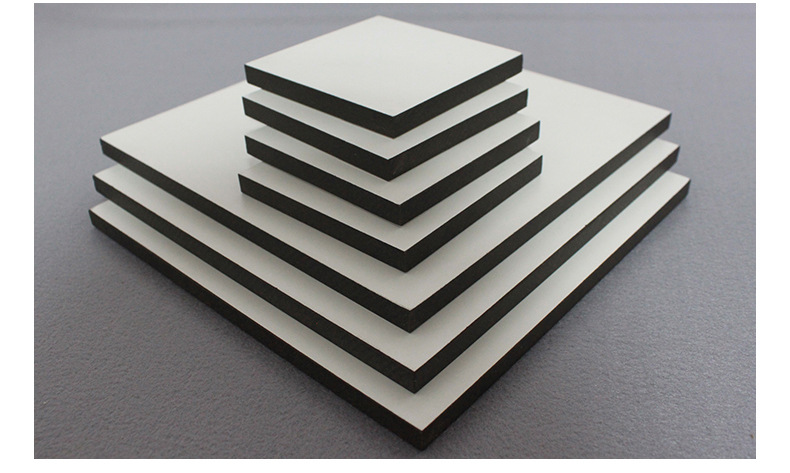

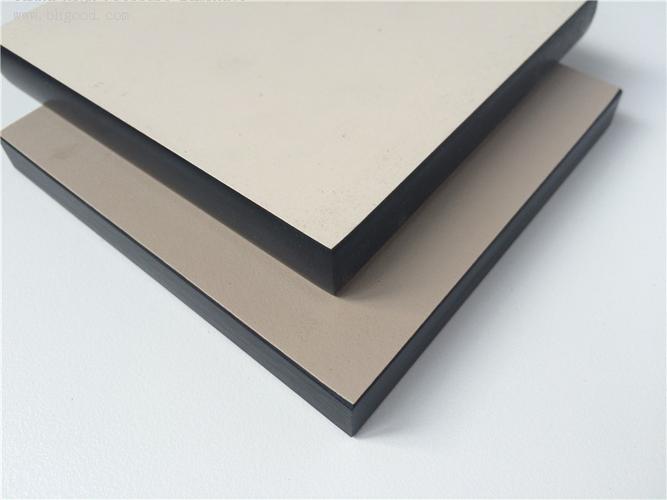

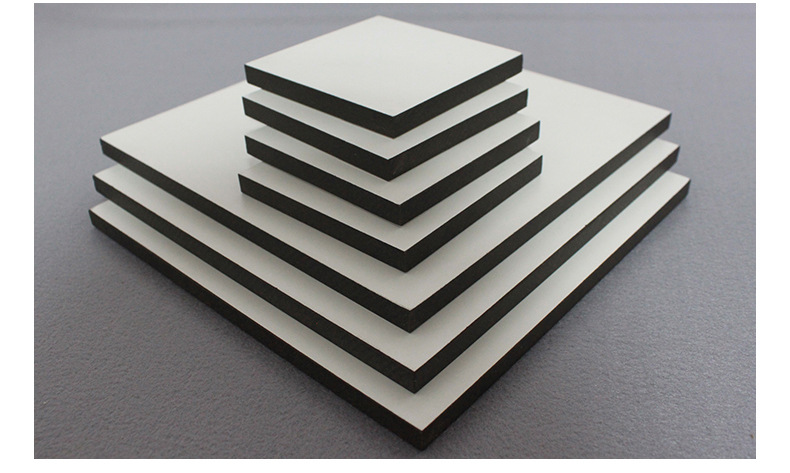

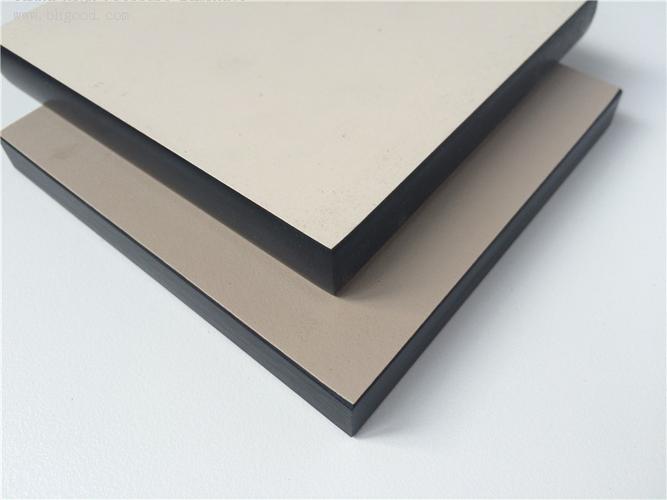

Compact laminate boards are high-performance building materials created through a process of layering kraft paper impregnated with phenolic resin, then compressing it under high temperature and pressure. This process results in a dense, durable panel that is resistant to water, moisture, mildew, insects, and chemicals.

They are widely used in both residential and commercial projects, including:

Because of their versatility and performance, compact laminate boards are a go-to solution for applications that demand strength, durability, and aesthetic appeal.

Main Types of Compact Laminate Boards

Compact laminate boards can be classified into several types depending on their surface finishes and intended applications:

1. Coated Compact Laminate Boards

These boards are treated with protective coatings such as polyester paint, fluorocarbon paint, or acrylic paint. The coating not only enhances visual appeal but also improves resistance to water, moisture, weather, and fire. They are suitable for both indoor and outdoor use, particularly in environments with high humidity or frequent cleaning.

2. Wood-Grain Compact Laminate Boards

Designed to replicate the natural look of wood, these boards use printing, embossing, or other decorative techniques to achieve a wood-like texture. They are ideal for interior applications such as furniture, wall panels, and cabinets, offering the warmth of wood with the durability of laminates.

3. Transparent or Colorless Compact Laminate Boards

Featuring a clear, smooth surface, these boards provide UV resistance and weather durability. Their transparency allows for creative applications, including decorative panels, signage, or modern interiors where natural lighting and aesthetics are key.

How to Identify Genuine Compact Laminate Boards

With the increasing number of suppliers, distinguishing between authentic and counterfeit compact laminate boards is essential. High-quality compact laminate boards ensure long-lasting performance, while fake or low-quality versions may compromise safety and durability. Here’s how you can identify genuine products:

1. Check the Brand and Manufacturer Credentials

Reputable compact laminate board manufacturers engrave essential information on their products, such as:

Brand name and trademark

Production date

Factory location

Product certification

When purchasing, verify these details carefully. Established brands with high visibility and strong reputations are generally more reliable and consistent in quality.

2. Examine the Production Process

The production method directly impacts the quality of compact boards. Manufacturers committed to quality often highlight their production process on official websites or product brochures. Look for boards manufactured under strict quality standards, typically involving advanced high-pressure and high-temperature lamination. Request product certifications or technical datasheets if available to confirm authenticity.

3. Inspect Key Performance Characteristics

a) Fire Resistance

Compact laminate boards are known for their fire-resistant properties, making them suitable for public spaces such as malls, schools, hospitals, and hotels. Authentic boards meet fire safety standards, so always check product certifications and brand credibility to ensure compliance.

b) Sound Insulation

High-quality compact laminate boards provide excellent acoustic performance, reducing noise transmission. This makes them ideal for applications such as office partitions, soundproof doors, or recording rooms. When possible, perform simple acoustic tests or request technical specifications to confirm their sound insulation capabilities.

c) Thermal Insulation and Non-Flammability

In addition to fire resistance, compact lamiante boards also act as effective thermal insulators, reducing energy consumption in buildings. Genuine boards maintain stable insulation performance, helping achieve energy efficiency goals. Inspect the product’s labeling for certifications that guarantee compliance with thermal and safety standards.

Why Authentic Compact Boards Matter

Choosing authentic compact lamiante boards ensures:

Safety: Genuine boards comply with fire and environmental safety standards.

Durability: High-quality boards last significantly longer than imitations.

Cost-effectiveness: Although authentic boards may have a higher upfront cost, they reduce long-term maintenance and replacement expenses.

Aesthetics: Premium brands offer superior finishes, textures, and colors for design flexibility.

Final Thoughts

Compact laminate boards are indispensable in modern construction and interior decoration due to their durability, versatility, and superior performance. From coated, wood-grain, to transparent options, they cater to diverse design needs. However, with the wide range of products available in the market, it is critical to identify genuine compact boards by examining brand reputation, production process, and performance characteristics.

Investing in authentic compact boards not only guarantees quality but also ensures safety, longevity, and design excellence for any project.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti

Runasimi