Laboratory countertops are essential components in scientific and research environments, providing durable and resistant surfaces for various experiments and procedures. Choosing the right material for these countertops is crucial, as it impacts the lab’s functionality, safety, and longevity. In this article, we delve into the application of Chemical resistant laminate boards and epoxy resin boards in laboratory countertops, highlighting their properties, advantages, and suitability for different lab settings.

Understanding Laboratory Countertops

Definition and Purpose

Laboratory countertops are specialized work surfaces designed to withstand the rigors of scientific experiments and daily lab activities. These countertops must be resistant to chemicals, heat, and mechanical stress to ensure a safe and efficient working environment.

Common Materials

Several materials are used for laboratory countertops, including Chemical resistant laminate boards, epoxy resin boards, stainless steel, and phenolic resin. Each material offers unique properties tailored to specific laboratory needs.

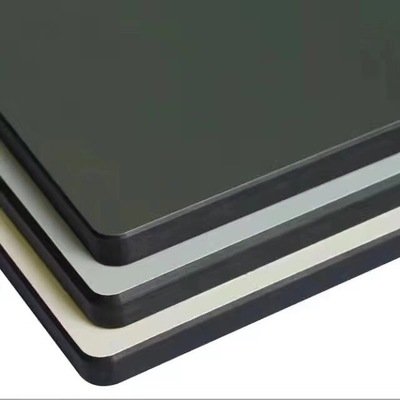

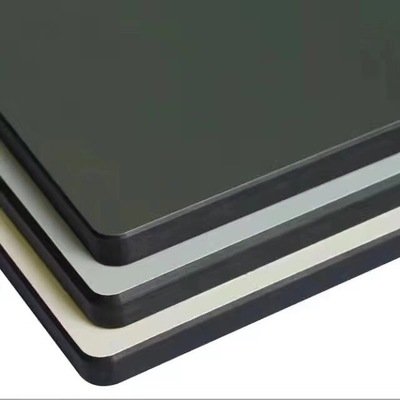

Chemical Resistant Laminate Boards

Composition and Properties

Material Composition

Chemical Resistant Laminate Boards are typically made from a combination of wood fibers and resins, treated to enhance their resistance to chemicals and physical wear. These boards are engineered to provide a balance between strength and flexibility.

Key Properties

High resistance to chemical spills and stains

Durable surface capable of withstanding mechanical stress

Moisture-resistant, preventing warping and degradation

Advantages

Durability

Chemical Resistant Laminate Boards are known for their exceptional durability. They can endure heavy usage and frequent cleaning without losing their structural integrity, making them ideal for busy laboratory environments.

Resistance to Chemicals

One of the standout features of these boards is their resistance to a wide range of chemicals. This property is particularly beneficial in chemistry and biology labs where chemical spills are common.

Applications in Laboratories

Chemistry Labs

In chemistry labs, where exposure to corrosive substances is frequent, Chemical resistant laminate boards provide a reliable surface that resists damage and ensures a safe working area.

Biology Labs

Biology labs benefit from these boards due to their ability to withstand the occasional spill of biological reagents and their ease of cleaning, which helps maintain a sterile environment.

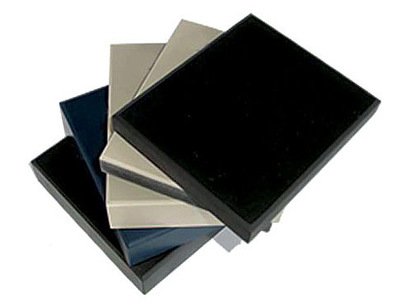

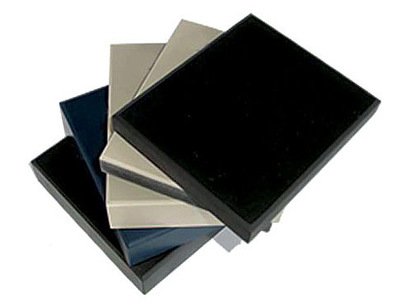

Epoxy Resin Boards

Composition and Properties

Material Composition

Epoxy resin boards are made from a mixture of epoxy resins and hardeners, creating a highly resilient and non-porous surface. This composition makes them incredibly tough and resistant to a variety of lab conditions.

Key Properties

Exceptional resistance to heat and chemicals

Non-porous surface that prevents absorption of liquids

Smooth, easy-to-clean finish

Advantages

Resistance to Heat and Chemicals

Epoxy resin boards are renowned for their ability to withstand high temperatures and exposure to harsh chemicals without degrading. This makes them suitable for labs dealing with high-temperature reactions or corrosive substances.

Non-porous Surface

The non-porous nature of epoxy resin boards ensures that no liquids or contaminants can penetrate the surface, making them hygienic and easy to sanitize.

Applications in Laboratories

Pharmaceutical Labs

Pharmaceutical labs, which require stringent cleanliness standards, benefit greatly from the non-porous and easy-to-clean surfaces of epoxy resin boards.

Research Facilities

In research facilities, where experiments often involve a variety of chemicals and processes, the robustness of epoxy resin boards provides a dependable and long-lasting work surface.

Chemical Resistant Laminate Boards vs. Epoxy Resin Boards

Durability

While both types of boards are durable, epoxy resin boards generally offer superior durability, especially in environments with high mechanical and thermal stress.

Resistance to Chemicals

Both materials are highly resistant to chemicals, but epoxy resin boards typically have an edge due to their non-porous surface, which prevents chemical absorption and staining.

Maintenance and Cleaning

Epoxy resin boards are easier to clean and maintain due to their smooth, non-porous surface. Chemical resistant laminate boards, while resistant to chemicals, may require more effort to keep clean over time.

Cost-effectiveness

Chemical resistant laminate boards are often more cost-effective initially but may require more frequent maintenance. Epoxy resin boards, though more expensive, offer longer-term savings due to their durability and low maintenance needs.

Factors to Consider When Choosing Laboratory Countertops

Type of Laboratory

The specific type of laboratory and its primary functions will significantly influence the choice of countertop material. For instance, chemistry labs may prioritize chemical resistance, while biology labs may focus on ease of cleaning.

Specific Requirements

Consider the unique requirements of your lab, such as the need for heat resistance, durability under heavy equipment, or resistance to specific chemicals.

Budget Constraints

Budget constraints are always a factor. Balancing the initial cost with long-term benefits and maintenance requirements is crucial in making an informed decision.

Installation and Maintenance of Laboratory Countertops

Installation Process

Proper installation of laboratory countertops is vital for ensuring their longevity and performance. It involves precise measurement, cutting, and secure fitting to avoid gaps and ensure stability.

Maintenance Tips

Regular Cleaning

Regular cleaning with appropriate cleaning agents is essential to maintain the integrity of the countertops and ensure a safe working environment.

Avoiding Damage

Avoid using abrasive materials or harsh chemicals that can damage the surface. Immediate cleaning of spills and regular inspections can help prolong the lifespan of the countertops.

Environmental and Safety Considerations

Eco-friendly Materials

Choosing materials that are eco-friendly and sustainably sourced is becoming increasingly important. Some modern laboratory countertops are made from recycled materials, contributing to environmental sustainability.

Safety Standards

Ensure that the chosen materials comply with relevant safety standards and regulations, providing a safe and compliant laboratory environment.

Conclusion

Choosing the right laboratory countertop material involves considering various factors, including durability, chemical resistance, maintenance needs, and cost-effectiveness. Compact solid physical and chemical boards and epoxy resin boards each offer unique benefits suited to different lab environments. By carefully assessing your lab's specific needs and constraints, you can select the most appropriate material to ensure a safe, efficient, and long-lasting work surface.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti

Runasimi