With the deepening of the concept of green living and environmental protection, eco-friendly building materials have become the mainstream choice for public area decoration. Wall panels, as a key part of public space design, not only need to meet the requirements of environmental protection but also bear the characteristics of high foot traffic, frequent contact, and complex environmental conditions in public places. Currently, compact laminate (HPL) and moisture-resistant boards are two commonly used materials for wall panels in public areas. But which one is more suitable? Which performs better in practical applications? Let’s analyze it in detail based on their core differences and public area usage scenarios.

First, Clarify the Core Differences: Materials & Basic Structure

The fundamental differences between the two materials lie in their raw material selection and manufacturing processes, which directly determine their subsequent performance and application scope.

1. Compact Laminate (HPL)

Also known as high-pressure laminate, its main raw materials are high-density wood fibers (wood powder) and thermosetting resins (such as phenolic resin). The production process involves impregnating multiple layers of kraft paper with resin, then pressing them under extreme conditions of high temperature (120–160℃) and high pressure (1000–1400 psi). The final product has a high-density, fully compact structure—no obvious gaps or pores can be seen, and the overall density is usually above 1.4g/cm³.

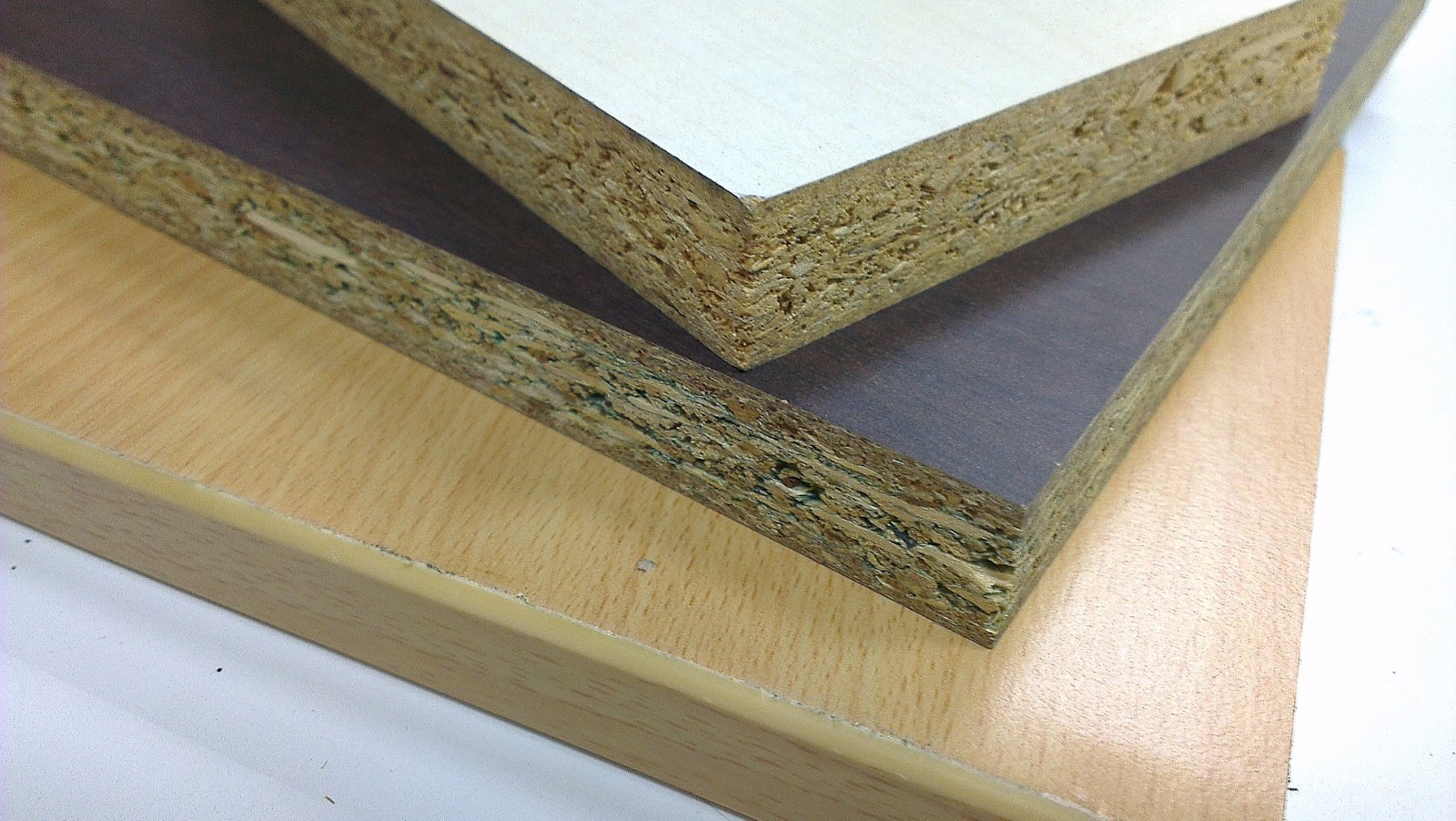

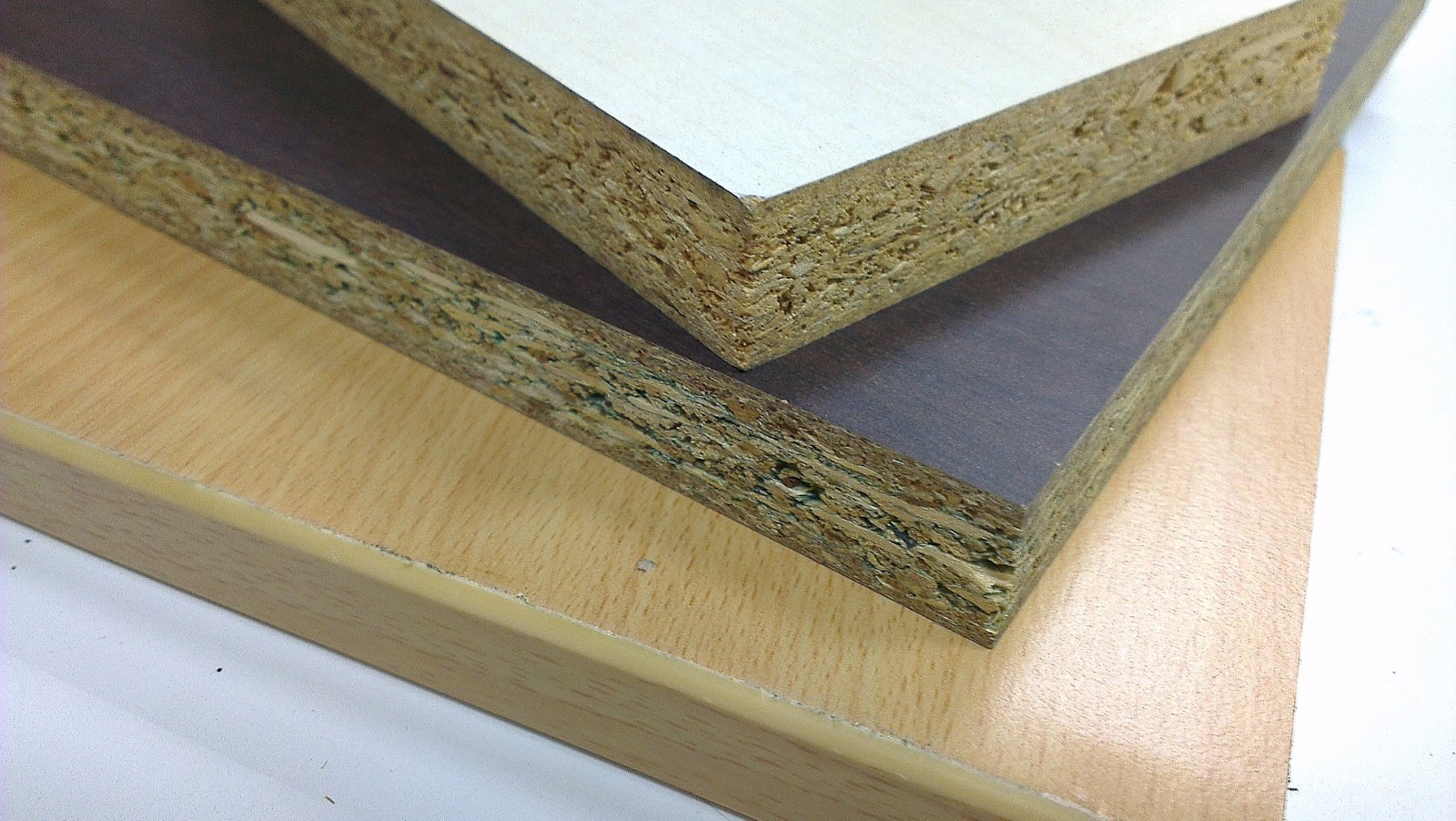

2. Moisture-Resistant Board

It is essentially an upgraded version of particleboard. The base material is wood shavings (wood chips), and during the production process, moisture-resistant agents (often visible as green or blue particles in the board) are added to the adhesive. It is bonded and pressed at medium temperature and pressure, so its structure is relatively loose compared to HPL, with obvious wood chip aggregates inside. Its core improvement is moisture resistance, but the basic structure still retains the characteristics of particleboard.

Key Comparison: Performance Against Public Area Wall Panel Demands

Public areas (such as hospitals, shopping malls, stations, and office buildings) have strict requirements for wall panels: they must be durable (resist collision and wear), easy to clean (resist stains), moisture-resistant (adapt to varying humidity), have good decorative appeal (match the space style), and be easy to maintain. Let’s compare the two materials against these core demands:

| Performance Index (Critical for Public Areas) | Compact Laminate (HPL) | Moisture-Resistant Board |

| Durability (Wear & Impact Resistance) | Excellent. The high-density compact structure enables it to withstand frequent collisions (impact strength ≥10kJ/m²) and friction. High-quality HPL can bear a pressure of up to 1450kg without deformation, and its surface wear resistance meets the international Class AC5 standard—suitable for high-traffic public areas where walls are often touched or leaned on. | Average. Its loose wood chip structure leads to poor impact resistance; it is prone to dents or even cracks when collided. The surface wear resistance is weak, and long-term contact or friction will easily cause the surface to peel or fade. It is difficult to meet the durability requirements of high-traffic public areas. |

| Moisture Resistance | Good. The resin-impregnated fully bonded structure is non-hygroscopic and does not swell or deform even in humid environments (such as underground passages, bathroom corridors, or coastal public areas). It can resist long-term moisture erosion without damage. | Moderate. It only has "moisture resistance" (not waterproof). The moisture-resistant agent can slow down the absorption of moisture, but if it is in a long-term high-humidity environment or encounters water immersion, it will still swell, deform, or even rot. It is only suitable for moderately humid areas, not for places with frequent water contact or high humidity. |

| Cleaning & Stain Resistance | Excellent. The surface is smooth and dense, with no pores, so it is not easy to absorb stains (such as ink, food residues, or medical reagents in public areas). Daily cleaning only requires wiping with a damp cloth and neutral detergent; stubborn stains can be removed without leaving marks. It also has corrosion resistance to common chemicals. | Poor. The surface has many tiny pores (due to the wood chip structure), which are easy to absorb stains and difficult to clean thoroughly. Once stained with oil or colored liquids, it is easy to leave permanent marks. In addition, it is not corrosion-resistant to chemicals and may be damaged when in contact with cleaning agents containing acid or alkali. |

| Decorative Appeal | Rich. The surface can be processed into various textures (such as wood grain, stone grain, solid color, and fabric texture) and hundreds of color options. It can be customized according to the design style of public areas (such as high-end shopping malls’ high-end texture, hospitals’ clean and simple style, or stations’ durable and bright style). The surface texture is natural and has a high-grade sense. | Simple. The surface color and texture are relatively single, mostly plain or simple wood grain. The decorative effect is rough, and it is difficult to match the high-end design needs of public areas. Usually, it needs to be painted or pasted with decorative paper for secondary processing, which increases the construction cost and may have problems such as peeling of the decorative layer in the later stage. |

| Maintenance Cost | Low. Due to its high durability and stain resistance, it basically requires no special maintenance after installation. Even if there is local damage, it can be partially replaced easily, and the overall maintenance cost in the later stage is very low. | High. It is prone to deformation, peeling, or staining, so it needs frequent maintenance (such as repainting, repairing dents, or replacing damaged parts). The secondary processing layer (such as paint or decorative paper) is easy to age and fall off in public areas with high traffic, leading to repeated maintenance and increased costs. |

| Environmental Protection | Good. High-quality HPL uses environmentally friendly thermosetting resins and meets E0-level formaldehyde emission standards (formaldehyde emission ≤0.124mg/m³). It does not release harmful gases during use, which is in line with the environmental protection requirements of public areas with dense crowds. | Depends on quality. Low-quality moisture-resistant boards may use inferior adhesives and moisture-resistant agents, leading to excessive formaldehyde emission. Even high-quality products have slightly higher formaldehyde emission than HPL due to the wood chip bonding process. It is necessary to strictly select products that meet national E1-level standards (formaldehyde emission ≤0.124mg/m³) for use in public areas. |

| Cost (Initial Investment) | Higher. The raw material cost and production process of HPL are more complex, so its unit price is usually 2–3 times that of moisture-resistant boards. The initial investment in large-area public area decoration is relatively high. | Lower. As an upgraded version of particleboard, its production cost is low, and the unit price is cheap, which can save the initial decoration budget. |

Scenario-Specific Recommendations for Public Area Wall Panels

Combined with the above performance comparisons, the choice of materials should be based on the specific type and environment of the public area:

1. Priority Choose Compact Laminate (HPL) for These Scenarios

High-traffic areas: Shopping mall corridors, station waiting halls, hospital outpatient halls, office building lobbies—where walls are frequently touched, leaned on, or collided.

Humid or special environment areas: Underground passages, bathroom corridors, coastal public areas, or laboratories (needing moisture resistance and chemical corrosion resistance).

Areas with high decorative and cleaning requirements: High-end shopping malls, exhibition halls, hotel lobbies—needing to match the design style and be easy to clean and maintain.

Reason: HPL’s durability, stain resistance, moisture resistance, and decorative appeal can fully meet the long-term use needs of these areas. Although the initial investment is higher, the low later maintenance cost and long service life (15–30 years) make it more cost-effective in the long run.

2. Moisture-Resistant Board Can Be Considered for These Scenarios (With Limitations)

Low-traffic, dry auxiliary areas: Public area storage rooms, equipment rooms, or secondary corridors with few people—where the wall panels are not easily touched or soiled, and the environment is dry.

Projects with extremely tight budgets: Temporary public facilities or low-cost renovation projects that do not require high durability and decorative appeal.

Note: If moisture-resistant boards are used in public areas, they must be subjected to secondary surface treatment (such as painting with anti-scratch and stain-resistant paint or pasting high-quality decorative film) to improve their wear resistance and stain resistance. At the same time, avoid using them in humid areas to prevent deformation and damage.

Final Conclusion

For wall panels in most public areas, compact laminate (HPL) is the more recommended choice. It can comprehensively meet the core demands of public areas for durability, easy cleaning, moisture resistance, and decorative appeal. Although the initial cost is higher, it has obvious advantages in long-term use (low maintenance cost, long service life, and stable performance).

Moisture-resistant boards, with their low initial cost, can only be used as a cost-saving option in limited scenarios (low-traffic, dry auxiliary areas) and require secondary processing to make up for their performance deficiencies. They are not suitable for mainstream public area wall panel applications that require high comprehensive performance.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti

Runasimi