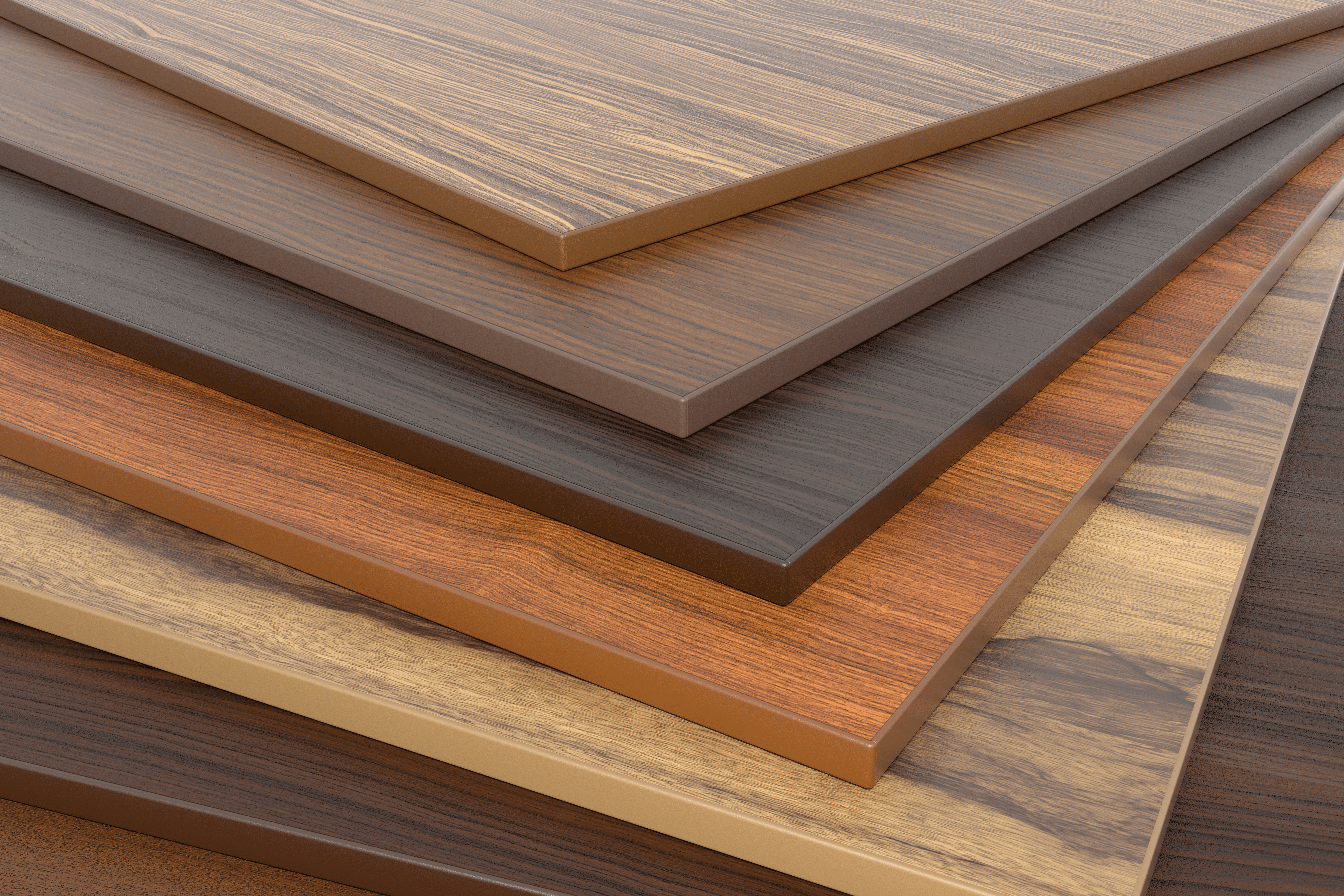

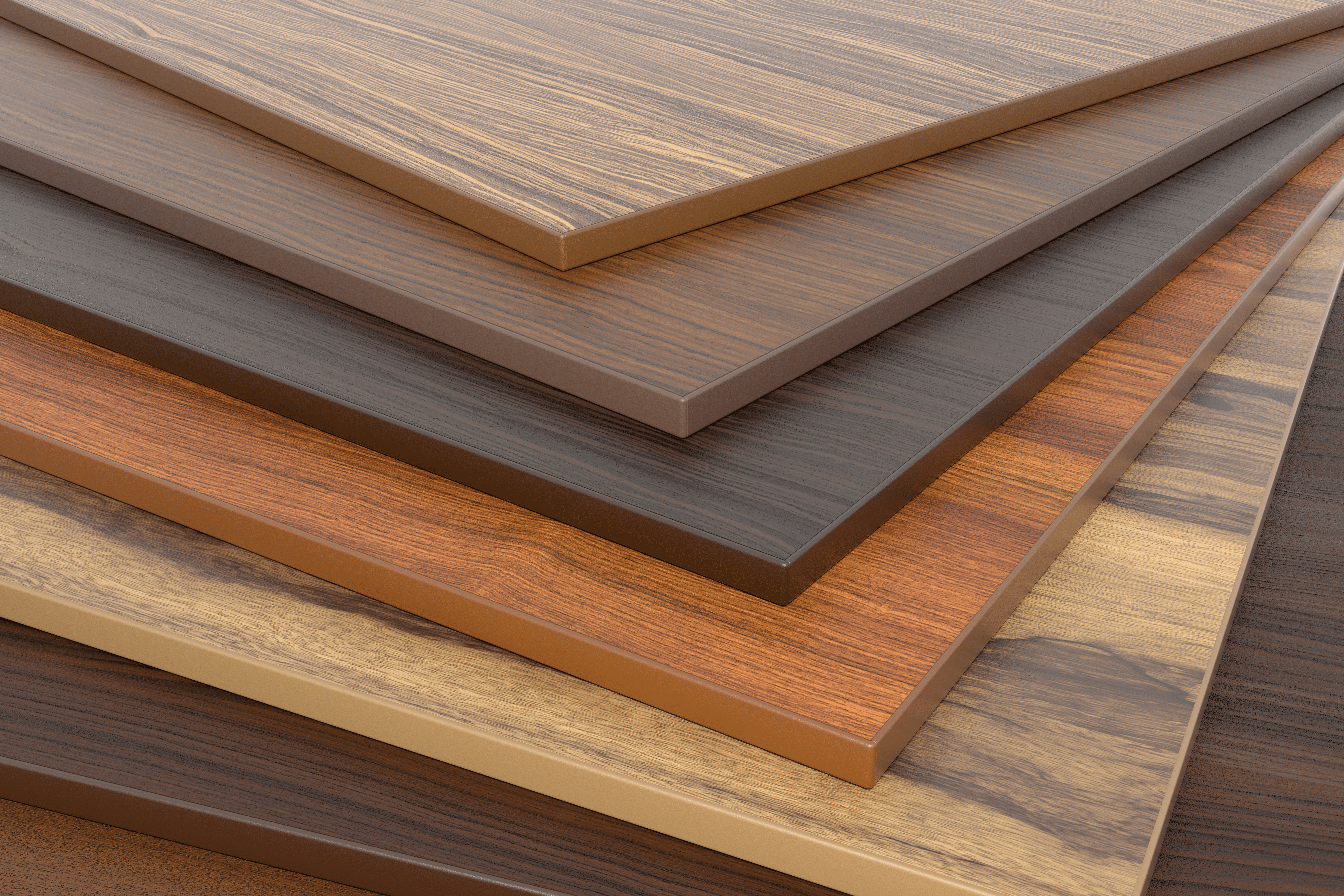

When it comes to modern interior design, furniture manufacturing, and architectural applications, laminates play an essential role in enhancing both functionality and aesthetics. Among the most commonly used laminate types are HPL (High-Pressure Laminate) and LPL (Low-Pressure Laminate). While they might sound similar, these two materials have significant differences in terms of composition, durability, performance, and cost. Understanding these differences is crucial if you want to choose the right material for your project.

In this article, we will explore the key differences between HPL and LPL, their manufacturing processes, advantages and disadvantages, applications, and how to decide which one best suits your needs.

1. What is HPL (High-Pressure Laminate)?

High-Pressure Laminate (HPL) is a surfacing material made by compressing multiple layers of kraft paper, a decorative sheet, and a protective overlay under high pressure (over 1,000 psi) and high temperature (around 120°C). This process creates a dense, durable, and versatile laminate sheet.

Key Features of HPL:

Highly durable and resistant to scratches, heat, and impact.

Comes in a wide variety of colors, textures, and finishes.

Often used in high-traffic areas due to its superior strength.

Resistant to moisture, chemicals, and wear.

HPL is commonly used for countertops, furniture, partitions, wall cladding, and flooring where durability is essential.

2. What is LPL (Low-Pressure Laminate)?

Low-Pressure Laminate (LPL), also known as melamine laminate, is produced by fusing a decorative paper layer directly onto a particleboard or MDF (medium-density fiberboard) core using low pressure (200–400 psi) and lower temperatures compared to HPL. Unlike HPL, LPL does not include multiple kraft paper layers.

Key Features of LPL:

More affordable compared to HPL.

Provides a wide range of decorative designs.

Suitable for light-duty applications.

Less resistant to scratches, moisture, and heat.

LPL is commonly used in residential furniture, shelving, cabinetry, and decorative panels where heavy wear and tear are not expected.

3. How Melamine Laminate is Made

Both HPL and LPL are based on melamine laminate technology. The process begins with impregnating decorative paper with melamine resin. A layer of kraft paper, impregnated with phenolic resin, adds strength and stability. These are combined with a decorative film layer (such as wood grain, solid colors, or patterns) and bonded to a wood substrate such as MDF or particleboard.

The main difference lies in how this laminate is bonded:

High-Pressure Laminate (HPL): The laminate is adhered to the substrate with adhesive at 70–100 Pa (1,000–1,500 psi) and a temperature of 280–320°F.

Low-Pressure Laminate (LPL): The laminate is bonded directly to the substrate without adhesive, under 20–30 Pa (290–435 psi) at a temperature of 335–375°F.

This explains why HPL is denser, stronger, and more resistant than LPL.

4. Durability Comparison

When it comes to durability, HPL clearly outperforms LPL:

HPL Durability:

Resistant to scratches, abrasions, and impacts.

Withstands heat, moisture, and chemicals.

Ideal for commercial spaces, kitchens, and bathrooms.

LPL Durability:

Prone to scratches, dents, and water damage.

Not recommended for high-moisture or high-traffic areas.

Better suited for low-impact residential use.

5. Fire-Retardant and Antimicrobial Properties

Both HPL and LPL have inherent flame-retardant and antimicrobial properties, making them safe and hygienic options. They are frequently chosen for food preparation areas, healthcare facilities, and educational spaces where cleanliness and safety are priorities. While both resist heat and chemicals, HPL offers slightly higher resistance, making it more suitable for demanding environments such as laboratories and commercial kitchens.

6. Appearance and Design Options

Both HPL and LPL offer a wide variety of designs, textures, and colors, but there are differences:

HPL: Available in premium finishes, including matte, glossy, textured, metallic, and woodgrain effects. Its designs are more realistic and refined.

LPL: Offers good decorative options but with less variety and depth compared to HPL. Finishes are simpler and more budget-oriented.

If aesthetics and realism are top priorities, HPL is the superior choice.

7. Cost Comparison

The most significant factor influencing the choice is price:

HPL: More expensive due to its complex manufacturing and enhanced durability.

LPL: More affordable, making it a good option for budget-conscious projects.

For short-term or decorative projects, LPL is sufficient. For long-term durability, HPL offers better value.

8. Applications of HPL

Because of its strength and resilience, HPL is widely used in demanding environments:

Kitchen countertops and cabinets

Laboratory and hospital surfaces

Office furniture and partitions

Wall cladding and decorative panels

Public restrooms and locker rooms

9. Applications of LPL

LPL is better suited for light-use applications:

Residential furniture (tables, wardrobes, drawers)

Shelving and bookcases

Low-traffic decorative panels

Budget-friendly cabinetry

10. Pros and Cons of HPL

Pros:

Extremely durable and long-lasting.

Resistant to scratches, moisture, chemicals, and heat.

Available in premium finishes and realistic designs.

Perfect for high-traffic and commercial spaces.

Cons:

11. Pros and Cons of LPL

Pros:

Affordable and budget-friendly.

Offers a wide range of decorative options.

Easy to fabricate and use in furniture production.

Cons:

Limited durability and lifespan.

Vulnerable to scratches, moisture, and heat damage.

12. Industry Examples

Some manufacturers use LPL as standard due to its affordability, but they often provide HPL alternatives for environments where extra strength is necessary. For example, in educational settings, HPL with a rounded “late edge” finish is popular, as it combines safety, durability, and aesthetics.

13. How to Choose Between HPL and LPL

When deciding between HPL vs. LPL, consider:

Budget – LPL is cheaper, but HPL offers long-term savings through durability.

Application – HPL is ideal for kitchens, bathrooms, labs, and commercial areas. LPL suits decorative or light-use furniture.

Longevity – HPL lasts longer and reduces replacement costs. LPL is better for short-term or budget projects.

Aesthetics – If you want high-end finishes, HPL offers more variety.

14. Sustainability Considerations

Both HPL and LPL can be eco-friendly when sourced responsibly:

Many products use FSC-certified boards and papers.

Some resins are formaldehyde-free for safer indoor use.

HPL’s longer lifespan makes it a more sustainable choice by reducing waste.

Look for certifications such as FSC, GREENGUARD, or LEED compliance to ensure sustainability.

Conclusion

The debate of HPL vs. LPL ultimately comes down to a balance between durability and affordability.

If you want a premium, long-lasting surface that withstands heavy use, moisture, and chemicals, HPL is the better choice.

If your project is budget-focused and will face light use, LPL is a practical solution.

Both materials are excellent in their own right. By carefully evaluating your project requirements, budget, and durability needs, you can make the right choice. Whether you choose HPL or LPL, laminates remain one of the most versatile and stylish materials for modern interiors and furniture design.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti

Runasimi